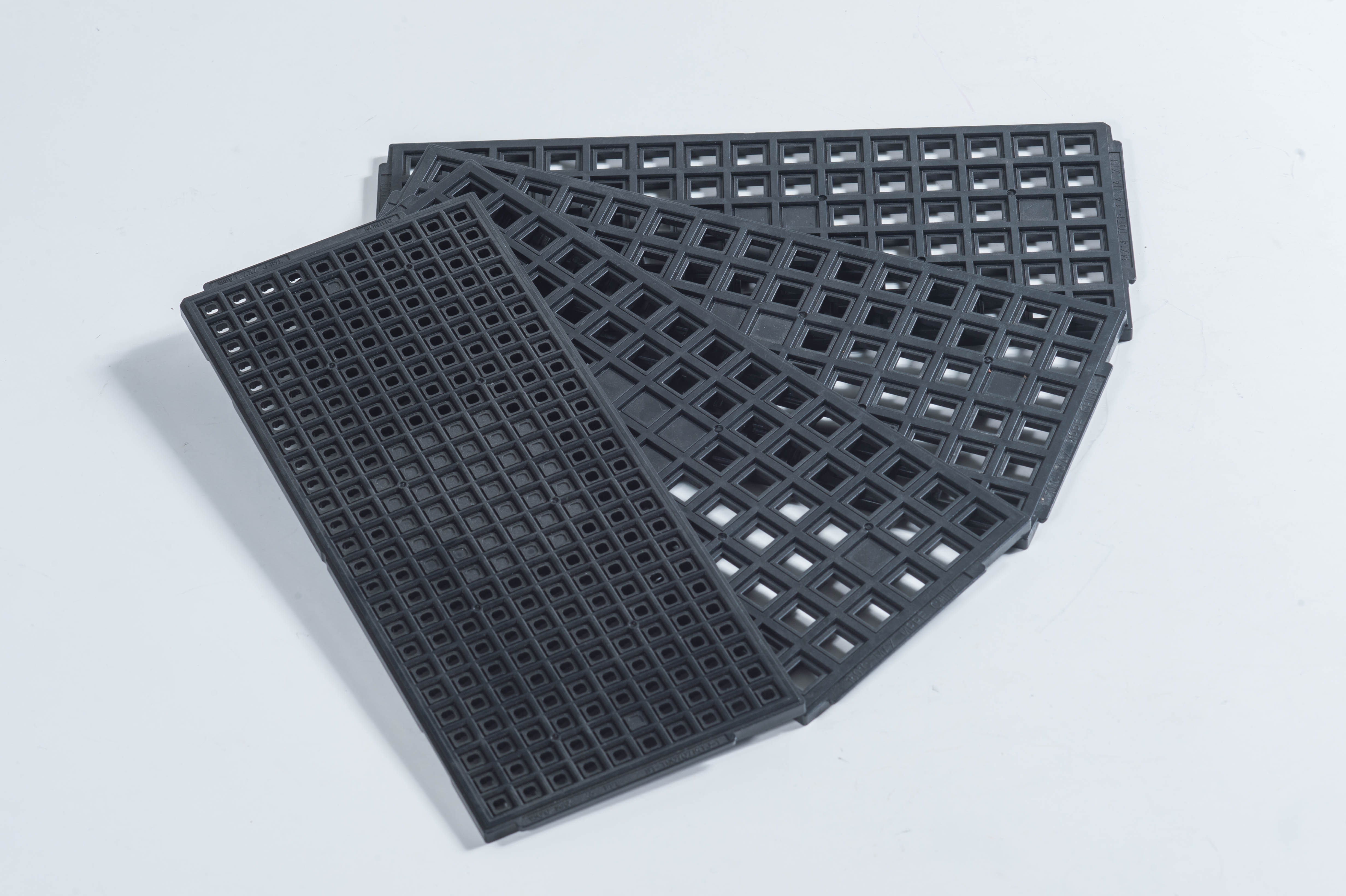

Conductive Rigid vinyl compound black material

欄目:Industry News 發(fā)布時(shí)間:2021-06-03 15:19

PVC plastic, chemical industry refers to compound polyvinyl chloride. The English name is polyvinyl chlorid, and the English abbreviation is PVC. This is the meaning of the wide use of PVC. Its natural col...

PVC plastic, chemical industry refers to compound polyvinyl chloride. The English name is polyvinyl chlorid, and the English abbreviation is PVC. This is the meaning of the wide use of PVC.

Its natural color is yellowish translucent and shiny. Transparency is better than polyethylene and polypropylene, but worse than polystyrene. Depending on the amount of additives, it can be divided into soft and hard polyvinyl chloride. Soft products are flexible and tough, and feel sticky. The hardness of hard products is higher than that of low-density polyethylene. When it is lower than polypropylene, whitening will occur at the inflection. Common products: plates, pipes, shoe soles, toys, doors and windows, wire sheaths, stationery, etc. It is a polymer material that uses a chlorine atom to replace a hydrogen atom in polyethylene.

Characteristic performance

PVC (Polyvinyl Chloride) Chemical and Physical Properties Rigid PVC is one of the widely used plastic materials. PVC material is a non-crystalline material. In the actual use of PVC materials, stabilizers, lubricants, auxiliary processing agents, pigments, reinforcing agents and other additives are often added [2].

PVC material has non-flammability, high strength, weather resistance and excellent geometric stability. PVC has strong resistance to oxidants, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated and concentrated, and is not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

The melting temperature of PVC during processing is a very important process parameter. If this parameter is not appropriate, it will cause material decomposition. The flow characteristics of PVC are quite poor, and its process range is very narrow. In particular, PVC materials with high molecular weight are more difficult to process (this material usually needs to be added with lubricant to improve flow characteristics), so PVC materials with low molecular weight are usually used. The shrinkage rate of PVC is quite low, generally 0.2~0.6%.

Injection mold process conditions

Melting temperature: 185~205℃ Mold temperature: 20~50℃

Injection pressure: up to 1500bar. Holding pressure: up to 1000bar. Injection speed: In order to avoid material degradation, a considerable injection speed is generally used.

Runners and gates: all conventional gates can be used. If processing smaller parts, it is better to use needle-point gates or submerged gates; for thicker parts, it is better to use fan gates. The small diameter of the needle-point gate or the submerged gate should be 1mm; the thickness of the fan gate should not be less than 1mm.

Typical uses: Water supply pipes, household pipes, house wall panels, commercial machine housings, electronic product packaging, appliances, food packaging, etc.

Simple structure

The structure is as follows: [―CH2 ―- CHCl― ]n

Molecular Structure

Material properties

Density: 1.380 g/cm3;

Young's modulus of elasticity (E): 2900-3400 MPa

Tensile strength (σt): 50-80 MPa

Elongation @ break 20-40%

Notch test 2-5 kJ/m2

Glass transition temperature: 87℃

Melting point: 212°C

Vicat (Vicat softening temperature) B1: 85℃

Thermal conductivity (λ) 0.16 W/m.K

Coefficient of thermal expansion (α) 8 10-5 /K

Heat capacity (c) 0.9 kJ/(kg&K)

Water absorption (ASTM) 0.04-0.4

Price 0.5-1.25

Melt index 6-9g/min

Molding conditions

Hard pvc

Material pipe temperature: 160-190℃

Mold temperature: 40-60℃

Drying temperature: 80℃x2h

Injection pressure: 700-1500kg/c㎡

Density: 1.4g/c㎡

Molding shrinkage: 0.1-0.5%

Meat thickness: 2.0-50.mm

Water absorption (24H): 0.1-0.4%

Melting softening point: 89℃

Heat distortion temperature: 70℃

Soft pvc

Material pipe temperature: 140-170℃

Mold temperature: 40-60℃

Drying temperature: 80℃x2h

Injection pressure: 600-1500kg/c㎡

Density: 1.4g/c㎡

Molding shrinkage: 0.1-0.5%

Meat thickness: 2.0-50.mm

Water absorption (24H): 0.1-0.4%

Melting softening point: 85℃

Heat distortion temperature: 55℃

Classification

rigid vinyl compound can be divided into soft PVC and hard PVC. Hard PVC accounts for about 2/3 of the market, and soft PVC accounts for 1/3. Soft PVC is generally used for floors, ceilings and the surface of leather, but because soft PVC contains softener (this is also the difference between soft PVC and hard PVC), it is easy to become brittle and difficult to store, so its scope of use is limited. Hard PVC does not contain softener, so it has good flexibility, easy to shape, not easy to be brittle, no pollution, long storage time, so it has great development and application value. Hereinafter all referred to as PVC. The essence of PVC is a kind of vacuum blister film, which is used for the surface packaging of various panels, so it is also called decorative film and adhesive film, which is used in building materials, packaging, and many other industries. Among them, the building materials industry accounts for a major proportion of 60%, followed by the packaging industry, and there are several other small-scale applications.

Performance

The combustion characteristics of polyvinyl chloride are: it is non-flammable, extinguishes when it is separated from the fire, the flame is yellow, white smoke, and the plastic becomes soft when it burns and emits a chlorine odor.

Polyvinyl chloride resin is a multi-component plastic, and different additives can be added according to different uses. Therefore, with different compositions, its products can exhibit different physical and mechanical properties, such as adding or not adding plasticizers to make it There are soft and hard products. Generally speaking, PVC products have the advantages of chemical stability, flame resistance, self-extinguishing, abrasion resistance, noise reduction, high strength, good electrical insulation, low price, wide material sources, and good airtight performance. The disadvantage is that it has poor thermal stability and is prone to aging under the action of light, heat and oxygen. The polyvinyl chloride resin itself is, if it is made of auxiliary materials such as plasticizers and stabilizers, it is harmless to humans and animals. However, most of the plasticizers and stabilizers used in polyvinyl chloride products generally seen in the market are toxic, so they cannot be used to contain food except for products with a specified formula.

⒈Physical performance

Polyvinyl chloride resin is a thermoplastic with an amorphous structure. Under ultraviolet light, hard PVC produces light blue or purple-white fluorescence, while soft PVC produces blue or blue-white fluorescence. The refractive index is 1.544 and the specific gravity is 1.40 when the temperature is 20℃. The density of products with plasticizers and fillers is usually in the range of 1.15 to 2.00, the density of flexible PVC foam is 0.08 to 0.48, and that of rigid foam is 0.03 ~0.08. PVC water absorption rate is not more than 0.5%.

The physical and mechanical properties of polyvinyl chloride depend on the molecular weight of the resin, the content of plasticizers and fillers. The higher the molecular weight of the resin, the higher the mechanical properties, cold resistance, and thermal stability, but the processing temperature is also required to be higher, and molding is more difficult; the lower molecular weight is the opposite of the above. As the filler content increases, the tensile strength decreases.

⒉Thermal performance

The softening point of polyvinyl chloride resin is close to the decomposition temperature. It has begun to decompose at 140°C, and decomposes more rapidly at 170°C. In order to ensure the normal progress of the molding process, two important process indicators are specified for polyvinyl chloride resin, namely decomposition temperature and thermal stability. The so-called decomposition temperature is the temperature when a large amount of hydrogen chloride is released, and the so-called thermal stability is the time when a large amount of hydrogen chloride is not released under a certain temperature condition (usually 190°C). Polyvinyl chloride plastic will decompose when exposed to 100℃ for a long time unless an alkaline stabilizer is added. If it exceeds 180℃, it will decompose rapidly.

The long-term use temperature of most polyvinyl chloride plastic products should not exceed 55°C, but the long-term use temperature of specially formulated PVC plastics(rigid vinyl compound

) can reach 90°C. Soft PVC products will harden at low temperatures. Polyvinyl chloride molecules contain chlorine atoms, so it and its copolymers are generally flame-resistant, self-extinguishing, and non-drip.

⒊Stability

Polyvinyl chloride resin is a relatively unstable polymer, which will also degrade under the action of light and heat. The process is to release hydrogen chloride and cause structural changes, but the degree is relatively light. At the same time, the decomposition will be accelerated in the presence of mechanical force, oxygen, odor, HCl and some active metal ions.

After the HCl is removed from the polyvinyl chloride resin, a conjugated double chain is formed on the main chain, and the color will also change. With the increase in the amount of hydrogen chloride decomposition, PVC resin changes from white to yellow, rose, red, brown and even black.

⒋Electrical performance

The electrical properties of PVC depend on the amount of residue in the polymer, the type and amount of various additives in the formulation. The electrical properties of PVC are also related to the heating conditions: when the heating causes the PVC to decompose, its electrical insulation will be reduced due to the presence of chloride ions. If a large amount of chloride ions are generated, they cannot be neutralized by alkaline stabilizers (such as lead salts). It will lead to a significant decrease in its electrical insulation performance. Unlike non-polar polymers such as polyethylene and polypropylene, PVC's electrical properties change with frequency and temperature, for example, the dielectric constant decreases with increasing frequency.

⒌Chemical properties

Polyvinyl chloride has very good chemical stability and is extremely valuable as an anti-corrosion material.

PVC is stable to most inorganic acids and alkalis, and will not dissolve when heated and will be separated into hydrogen chloride. Azeotrope with potassium hydroxide to prepare brown and insoluble unsaturated products. The solubility of PVC is related to molecular weight and polymerization method. Generally speaking, the solubility decreases as the molecular weight of the polymer increases, and the solubility of the emulsion resin is worse than that of the suspension resin. It can be dissolved in ketones (such as methylhexanone, cyclohexanone), aromatic solvents (such as toluene, xylene), dimethylformyl, and tetrahydrofuran. Polyvinyl chloride resin is almost insoluble in plasticizers at room temperature, and it swells significantly or even dissolves at high temperatures.

⒍Processing performance

PVC is an amorphous polymer with no obvious melting point and has plasticity when heated to 120-150°C. Because of its poor thermal stability, a small amount of HCl is released at this temperature, which promotes its further decomposition, so alkaline stabilizers and HCl must be added to inhibit its catalytic cracking reaction. Pure PVC is a hard product, and it needs to add an appropriate amount of plasticizer to make it soft. For different products, it is also necessary to add additives such as ultraviolet absorbers, fillers, lubricants, pigments, and anti-fungal agents to improve the quality of PVC products. Use performance. Like other plastics, the performance of the resin determines the quality and processing conditions of the product. For PVC, the resin properties related to processing are: particle size, thermal stability, molecular weight, fish eyes, bulk density, purity, foreign impurities, and porosity. For PVC paste and the viscosity and gelatinization properties of the paste, it is necessary to try to determine the processing conditions and product quality.

Copolymerization modification

Introducing its monomers into the main chain of vinyl chloride to copolymerize, the result is a new type of polymer that includes two monomeric links. This polymer is called a copolymer. The main varieties and properties of copolymers of vinyl chloride and other monomers are as follows:

⑴Vinyl chloride-vinyl acetate copolymer: The introduction of vinyl acetate monomer can act as a general plasticizer, which is also called "internal plasticization", which can avoid the volatilization, migration, and extraction of general plasticizers. It can also reduce the melt viscosity, reduce the processing temperature, and improve the processing performance. Generally, the content of vinyl acetate in the copolymer is 3-14%.

The main disadvantages of vinyl chloride-vinyl acetate copolymers are reduced tensile strength, heat distortion temperature, abrasion resistance, chemical stability and thermal stability.

⑵Vinyl chloride-vinylidene chloride copolymer: The plasticization, softening temperature, solubility and intramolecular plasticization of this copolymer are basically the same as those of vinyl chloride-vinyl acetate copolymer. Its major characteristics are low water and gas permeability, high solubility in ketone solvents, and resistance to the dilution of aromatic hydrocarbons, so it can be effectively used in coatings. In addition, it is also used to make shrink films. Because the heat resistance and light stability are worse than that of vinyl chloride-vinyl acetate copolymer, and the monomer cost is higher, it is not as widely used as vinyl chloride-vinyl acetate.

⑶Vinyl chloride-acrylate copolymer: The internal plasticizing effect of this copolymer is equivalent to that of vinyl chloride-vinyl acetate, and it has good thermal stability. It can be used to manufacture hard and soft products, improve processability and impact resistance. And cold resistance. It can also be used for coating and bonding.

⑷Vinyl chloride-maleate copolymer: The content of maleate in this copolymer is about 15%, and its internal plasticization is similar to that of vinyl chloride-acrylate. Has good processing performance. The physical and mechanical properties are less reduced, and the heat resistance is higher than that of general copolymers.

⑸Vinyl chloride-olefin copolymer: copolymerize olefin monomers such as ethylene and propylene to obtain copolymer resins with excellent fluidity, thermal stability, impact resistance, transparency, and heat resistance.

Blending modification

PVC resin is a polar non-crystalline polymer, density: 1.380 g/cm3, glass transition temperature: 87°C, so it has poor thermal stability and is difficult to process. It cannot be used directly, it must be modified and mixed, and related additives and fillers can be added. However, due to the different types and fractions of the related additives and fillers added, this determines that the properties and requirements of the prepared PVC materials are different. We usually call it PVC formula, strictly speaking it is PVC modified formula, and PVC can only be used after modification. This category is often classified as polymer modified materials. [3] Material modification mainly focuses on research on the high performance of general-purpose plastics, the conversion of single-component materials to multi-component composite materials (alloys, blends, and composites), functionalization of materials, and optimization of performance and price. The modification methods are mainly chemical modification, filling modification, reinforcement modification, blending modification and nano composite modification. The basic principle of modification is to give materials functions or improve certain properties through additives. Therefore, the level of PVC formulation technology determines the level of technology and production capacity of a factory. PVC materials with special requirements generally need to be imported from abroad. The more famous foreign companies include United Carbon and Borealis. With the continuous R&D and technology accumulation of major scientific research institutes and production units in my country, domestic PVC reform The formulation design and manufacture of sexual materials have reached the international level, and companies with independent intellectual property rights such as Xuzhou Hanyong New Materials Co., Ltd. have emerged, which have completely replaced foreign imported materials, and many products have been exported abroad.

It is a simple and effective modification method to introduce heterogeneous polymer phase-polymer blending and melting in the polyvinyl chloride phase, and has accumulated experience in actual production. Generally, when two or more different polymers are blended and melted, a mixture with the properties of these polymers can be prepared.

In order to improve the fluidity and impact performance of rigid polyvinyl chloride, the commonly used polymer blends are: acrylonitrile-butadiene-styrene (ABS), which is mainly to improve the impact strength. Methyl methacrylate-butadiene-styrene (MBS), except for weather resistance, all other properties are close to ideal, especially the impact strength, which can be greatly improved by adding a small amount. Chlorinated polyethylene (CPE) can improve the impact strength, if added 20%, the impact strength can be very high. Ethylene Vinyl Acetate (EVA) Can improve impact strength.

In order to improve the volatilization, migration and extraction of plasticizers of soft polyvinyl chloride during use, the commonly used polymer blends are: nitrile rubber (NBR), chlorinated polyethylene (CPE), vinyl chloride-acrylate , Copolymers such as dioctyl maleate, ethylene-vinyl acetate (EVA), ethylene-vinyl acetate-vinyl chloride copolymer, etc.

Graft polymerization

The introduction of other monomers on the side chain of polyvinyl chloride or the introduction of vinyl chloride chain on the side chain of a heterogeneous polymer is called graft polymerization.

⒋Low temperature polymerization

Changing the arrangement of the chain links in the main chain of polyvinyl chloride or changing the arrangement of the polyvinyl chloride chains means changing the polymerization method. This modification is called low-temperature polymerization.

Synthesis

PVC plastic is made by synthesizing vinyl chloride from acetylene gas and hydrogen chloride, and then polymerizing it. In the early 1950s, it was produced by the acetylene carbide method, and in the late 1950s, it turned to the ethylene oxidation method with sufficient raw materials and low cost; more than 80% of the PVC resin was produced by this method. But after 2003, due to the soaring oil price, the cost of the acetylene calcium carbide method was about 10% lower than that of the ethylene oxidation method, so the PVC synthesis process turned to the acetylene calcium carbide method.

PVC plastic is made by polymerization of liquid vinyl chloride monomer (VCM) through suspension, emulsion, bulk or solution process. The suspension polymerization process has mature production technology, simple operation, low production cost, many product varieties, and a wide range of applications. It has always been the main method of producing PVC resin, accounting for about 90% of PVC production equipment (homopolymer also accounts for about 90% of total PVC production). The second is the emulsion method, which is used to produce PVC paste resin. The polymerization reaction is initiated by free radicals, and the reaction temperature is generally 40 to 70 OC. The reaction temperature and the concentration of the initiator have a great influence on the polymerization reaction rate and the molecular weight distribution of the PVC resin.

Formula selection

The formula of PVC plastic profile is mainly composed of PVC resin and additives. The additives are divided into heat stabilizers, lubricating agents, processing modifiers, impact modifiers, fillers, anti-aging agents, and coloring agents according to their functions. Wait. Before designing PVC formula, we should first understand the performance of PVC resin and various additives.

1. The resin should be PVC-SC5 resin or PVC-SG4 resin, that is, polyvinyl chloride resin with a degree of polymerization of 1200-1000.

2. A thermal stability system must be added. Choose according to the actual requirements of the production, pay attention to the synergistic effect and antagonistic effect between the heat stabilizers.

3. Impact modifier must be added. Can choose CPE and ACR impact modifiers. According to the other components in the formula and the plasticizing capacity of the extruder, the addition amount is 8-12 parts. CPE is low in price and has a wide range of sources; ACR has high aging resistance and solder fillet strength.

4. Add an appropriate amount to the lubrication system. The lubrication system can reduce the load of the processing machinery and make the product smooth, but an excessive amount will cause the strength of the weld angle to decrease.

5. Adding processing modifiers can improve the quality of plasticization and improve the appearance of products. Generally, ACR processing modifier is added in the amount of 1-2 parts.

6. Adding fillers can reduce costs and increase the rigidity of the profile, but has a greater impact on low-temperature impact strength. The active light calcium carbonate with higher fineness should be selected for addition, and the addition amount is 5-15 parts.

7. A certain amount of titanium dioxide must be added to shield ultraviolet rays. Titanium dioxide should be rutile type, and the addition amount is 4-6 parts. When necessary, ultraviolet absorbers UV-531, UV327, etc. can be added to increase the aging resistance of the profile.

8. Adding appropriate amount of blue and fluorescent whitening agent can significantly improve the color of the profile.

9. The design formula should be simplified as much as possible, and no liquid additives should be added as much as possible, and the formula should be divided into No. I, No. II, and No. III materials in batches according to the order of addition according to the mixing process requirements (see the mixing problem).

Suspension polymerization

Suspension polymerization keeps the monomer droplets in suspension in water through continuous stirring, and the polymerization reaction proceeds in small monomer droplets. Generally, suspension polymerization is batch polymerization.

In recent years, various companies have continuously researched and improved the formula, polymerization vessel, product variety and quality of the PVC resin batch suspension polymerization process, and have developed unique process technologies. The technology of Geon (formerly BF Goodrichg) has been more widely used. The technology of Shin-Etsu Corporation of Japan and the technology of EVC Corporation of Europe, the technologies of these three companies each account for approximately 21% of the newly added PVC resin production capacity since 1990.

Emulsion polymerization

Emulsion polymerization is basically similar to suspension polymerization, except that a larger amount of emulsifier is used, and it is not dissolved in water but in monomers. This kind of polymerization system can effectively prevent the agglomeration of polymer particles, thereby obtaining a polymer resin with a small particle size. Generally, the particle size of the PVC resin produced by the emulsion method is 0.1-0.2mm, and the suspension method is 20-200mm. The initiator system is also different from suspension polymerization, and is usually a redox system containing persalt. The drying method is also designed to maintain a smaller particle size, and some spray desiccants are often used. Since it is impossible to completely remove the emulsifier, the resin produced by the emulsion method cannot be used to produce products that require high transparency such as packaging films or products that require low water absorption such as wire insulation. Generally speaking, the price of emulsion polymerized PVC resin is higher than that of suspension polymerized resin, but users who need to compound in liquid form use this resin, such as paste resin. Most of the emulsion polymerized resin products in the United States are paste resins (also called dispersion resins), and a small amount is used in latex. In Europe, various emulsion processes are also used to produce general-purpose resins, especially resins for calendering and extrusion.

Bulk polymerization

The bulk production process performs polymerization under the conditions of anhydrous, no dispersant, and only the addition of initiators, no post-processing equipment is required, and low investment, energy saving, and low cost. The products produced by the bulk method PVC resin have high transparency, good electrical insulation, and easy processing. The equipment used to process the suspension method resin can be used to process the bulk method resin. The PVC body process has been greatly developed in the 1980s. However, although in theory the resins produced by the suspension and bulk polymerization processes can be used in the same field, in fact processing plants generally only use one of them, because the suspension and bulk resins cannot be mixed, and even a small amount of mixing will cause electrostatic effects. As a result, the fluidity of the polymer powder is reduced, and the suspension polymer resin is more readily available. Therefore, most processing plants abandon the bulk resin. In recent years, the bulk process has stagnated or declined.

Solution polymerization

In solution polymerization, the monomer is dissolved in an organic solvent (such as n-butane or cyclohexane) to initiate polymerization, and the polymer precipitates as the reaction proceeds. Solution polymerization is specially used to produce special vinyl chloride and vinyl acetate copolymers (usually the vinyl acetate content is 10-25%). The copolymer produced by this solution polymerization reaction is pure, uniform, and has unique solubility and film-forming properties.

Application and classification

PVC needs to add additives in the processing, in order to be able to produce a variety of soft, hard, transparent, good electrical insulation, foam and other products that meet people's needs. The combination of different types of PVC resins and various additives can produce Pvc materials for different applications. The most common is the loose resin produced by the suspension method, commonly known as SG resin combination. (Derived from "caustic soda and PVC production technology" Author: Wang Jing, Hu Jiuping 2012.2 published).

Model Level Main Purpose

SG1 Class A Advanced Electrical Insulating Material

SG2 Class 1 A electrical insulating material, film Class 1 B, Class 2 General soft products

SG3 Class 1 A electrical insulating material, agricultural film, artificial leather surface film Class 1 B, Class 2 All plastic sandals

SG4 Class 1 A Industrial and civil film Class 1 B, Class 2 hose, artificial leather, high-strength pipe

SG5 Class 1 A transparent product Class 1 B, Class 2 Hard tube, hard piece, monofilament, catheter, profile

SG6 first-level A record, transparent film first-level B, second-level hard board, welding rod, fiber

SG7 Class 1 A bottle, transparent sheet Class 1 B, Class 2 Hard injection pipe fittings, Perchlorovinyl resin

Wuxi Jiahong Plastic Technology Co., Ltd. can dye and process ABS, PS, PC, PC/ABS, PP and other engineering plastic particles according to customer requirements; various filled, flame retardant, reinforced modified ABS, PP, PC/ABS, PA and other engineering plastics Particles; various automotive special materials such as door panels, bumpers, dashboards, engine covers, car lights, etc.

Wuxi Jiahong Plastic Technology Co., Ltd. has nearly 30 years of experience in R&D and pelletizing production of rigid vinyl compound, and experience in R&D and production of modified engineering plastics; the professional technical service team can provide customers with one-stop modified plastic system solutions. If you want to know more about the product, please log in to our official website: www. js-plastics. com, consult online customer service or call the hotline. Landline: 0510-68755207 Mobile: 15190220696, we will serve you wholeheartedly.

(Disclaimer: All tutorials and resources included in this site are from the Internet, and their copyright belongs to the original author and his website. Although this site strives to preserve the original copyright information, it may not be able to be determined due to many reasons. The true source, please forgive the original author! If you have any objections to the attribution of the tutorials and resources on this site, please notify the editor immediately. The situation is true and we will delete it as soon as possible.)